Recent Posts

Metric vs Imperial Oil Seals: Why You Need the Perfect Fit

Posted by on

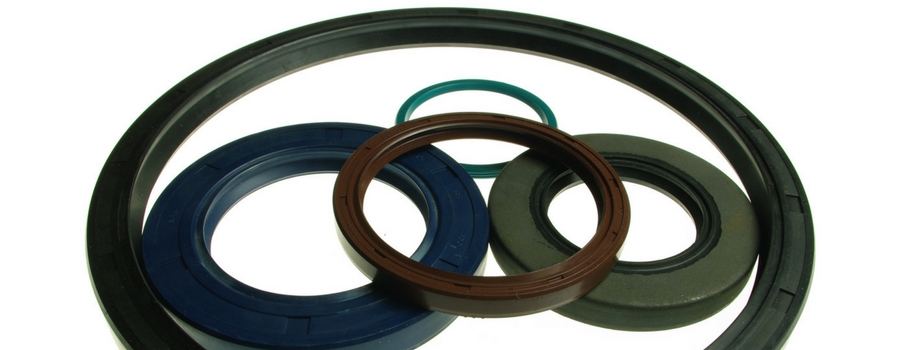

Oil seals play a key part in machine operation and lifetime maintenance in most factories. Since so much of factory and machine production is not standardized, a business needs to be able to quickly source both imperial and metric oil seals.

A Perfect Fitting Oil Seal

Whether in imperial or metric measurements, a rotary oil seal prevents dirt build-up and wear and tear on a rotary machine. The average consumer does not understand how many different measurements there are in machine uses, between the metric and imperial system. An experienced machinist and factory floor manager knows that there are many close fitting seals.

An imperial seal may be close to a metric equivalent. But, if the machine the seal is going on is designed with metric measurements, then an imperial measurement oil seal will never match. An ill-fitting oil seal will cause rotary problems, busted parts, and slow functioning machines. When you consider purchasing oil seals for your factory, it is important that you buy from a retail team that understands how to help you get the right fit for each machine. This reduces costs and increases the output of your machines.

Factory, Agriculture, and Shop

Oil seals are not just for a traditional factory floor. Since machines are used in so many areas of life, it pays small business owners to plan their machine maintenance. A farm may not have as many needs for metric and imperial oil seals as a large factory. Therefore, it is important that a farmer ensure that they have seals fitting the metric or imperial measurements of their machines. When ordering less parts, it may be tempting to just make do with the parts on hand, but a small farm cannot afford to replace a machine. The right fitting oil seal will increase the life span of the machines on the farm.

Likewise for a small shop, except here the need for a perfect fit is even greater. On a farm, there are a limited number of pieces of machinery that need protection. In a large-scale factory, there are multiple machines using interchangeable parts that make for easy ordering. In a small shop (mechanic, electrical and HVAC, artisan, etc.), there are multiple machines with specific measurements. There might not be too of the same machines with the same size parts. For small shop owners and employees in charge of parts, you must make sure to use the right size oil seal, whether metric or imperial.

Service-Based Retail

Between Amazon and Walmart, people expect to buy parts from a cheap, impersonal business. This is not the best idea when selecting a perfect fit for your machines. Metric and imperial measurements are only one aspect to consider when looking for oil seals for your machines. As we discussed earlier, design, application, size, and qualityof the seal also matter. The exposure of the seal to various elements in nature or on a production floor (water and other chemicals) matters. There are many factors to consider when selecting a seal for a machine, and a service-based sales team will have the resources to help you in that decision.

Metric vs imperial is one set of measurements that can make or break a maintenance schedule. Do not trust what is often the most valuable asset a business owns, its Plant and Equipment to cheap and easy. Find a service-based sales team that works with wholesalers to ensure that your business only gets the best quality oil seals, no matter your size. Since 2005, we have been working with our customers, ensuring not only a great online shopping experience, but accurate measurements and quality product. Contact us today to find out if we have the right materials to keep your machines running smoothly, or feel free to browse our oil seals.