Recent Posts

Five Causes for Premature V-Belt Failure

Posted by on

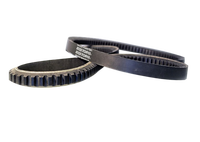

One of the most frustrating parts of production is when it stops. The job has to get done, usually under a deadline, so stoppage time makes everything more difficult. More stress, annoyance, and the costly overtime frequently accompany down time. In short, it costs you money and life span! One of the components that can bring work to a screeching halt is the V-Belt. When it breaks, you have to change it out. Here are the primary reasons for V-Belt failure that you should be aware of to address any issues you might be having.

V-Belt Reasons for Breakage

- Poorly or Improperly Maintained: This is the leading cause of V-Belt failure. It accounts for nearly half of the premature V-Belt malfunctions. The belt must have a high level of friction for gripping, and the proper amount of tension. The belt drive must also be tensioned correctly, designed for the job at hand,and properly installed with new and according parts.These factors are subject to change or wear down over time, and neglectful and poor maintenance that follows takes a toll. Misalignment, poor tensioning, and sheaves (pulleys) that are worn out are often major contributors.

- Design Flaws: Coming in at number two, with roughly 1/5 of all V-Belt early endings to it's credit, is design flaws. Whether it's the drive not compatible with the equipment that was originally in place, or some customized modifications to increase load or speed, this is a leading cause of malfunctions. Fortunately, most manufacturers offer software free of charge for creating the right belt for what you need. Certain information is required of course, such as type of belt needed, RPM's and horsepower, pulley speed, servicing requirements, and so on. But this will help eliminate issues that arise from improper belt usage due to incorrect design.

- Incorrectly Installed: Tension is a major part of proper V-Belt function. Ideally, you want the tension to be as light as possible without causing any slippage during highest capacity loads for best results. The drive must also be aligned correctly. Poor alignment will reduce the duration of a V-Belt's lifespan, and cause it to have stability problems.

- The Environment: Whether it's from extreme heat, or dirty or dusty conditions, the environment has an affect on a V-Belt. The optimal temperature for an operational V-Belt is right around 140 degrees fahrenheit. Though many are designed to run despite being hotter than that, after about 8 degrees more, they start to break down, and can lose up to half of their expected duration. Also, dirt, sawdust, and other contaminates can wear on the surface of the belt, also diminishing it's lifespan.

- Defects and Poor Handling: While rare, occasionally defects can be blamed for a short belt life. If you are storing your V-Belt, don't hang it from a hook, as this can cause the belt to crimp. This is especially true of large or heavy belts. Instead, find a flat surface to store it. Also, as previously mentioned, excessive heat can damage your belt, so avoid that issue whenever possible.

If you take good care of your V-Belts and the parts that connect to it, you'll already be halfway to better results with regards to longevity. And if you use the correct size and proper installation and usage, you will eliminate nearly all issues that can cause premature failure. For everything you need to keep your industry machine rolling, check out The Big Bearing Store and it's huge inventory of ready to ship parts and bearings.